Desoi Injection Technology

Building Strength from the Inside Out

At Rohhri Enterprises LLP, we specialize in advanced injection technology and structural repair systems, serving civil, infrastructure, and industrial sectors. As an authorized distributor of DESOI, a global leader in injection systems, we bring German precision to India’s growing infrastructure needs.

We also supply a comprehensive range of Indian-manufactured grouting pumps, packers, and manual injection equipment, ensuring high performance and cost-effective solutions for all project scales.

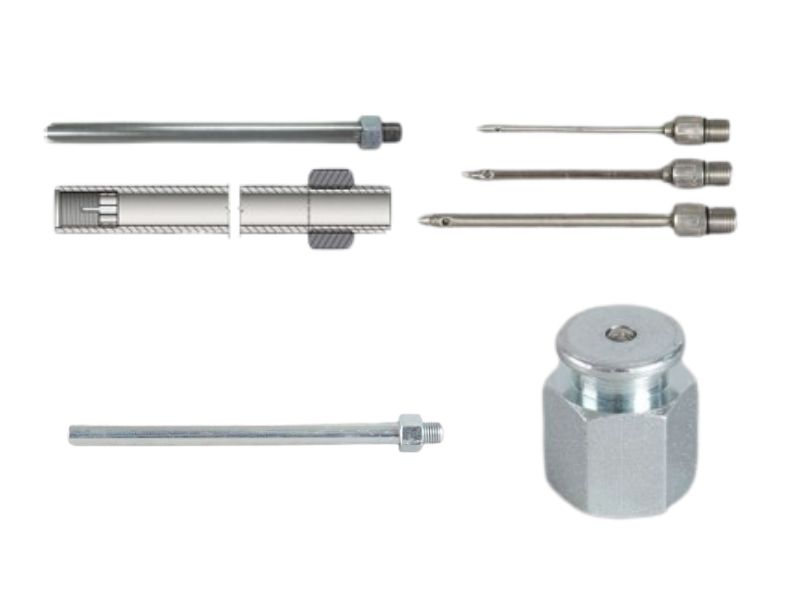

INFLATABLE PACKERS

Inflatable packers are used for injections in nearly all areas of the boring technology, tunneling, and special civil engineering. These injections generally serve for the improvement of mechanical properties or for sealing purposes. Moreover in the field of borehole measurement technique inflatable packers are used for test injections, water pressure tests, and for geological reconnaissance boreholes.

Examples of application:

– Consolidation of ground in different depths

– Consolidation of unconsolidated material

– Consolidation of fissured solid rock

– Injections in building components

– Injections into the soil below building components

– Sealing works

– Lifting injection

Advantages:

– Reusable

– Material-conducting parts of stainless steel or with hardened sealing surface

– Easy and safe sealing of boreholes

– Can be used in different depths

– All parts are easily exchangeable

– Installation

Depending on the type of packer a securing cord or the material hose is used to place the packer in the borehole. The inflatable packer is lowered in the borehole either by the securing cord or the material hose. After the injection the packer can be safely removed and reused. If the borehole is not vertical the inflatable packer must be placed with linkage.

HIGH PRESSURE GROUTING PUMPS

DESOI AirPower S25-2C Set

Carrying frame, 1.5 m suction system Ø 20 mm with suction basket Ø 40 mm: component A: transparent, component B: black, 2 x manometer 0 – 250 bar, material hose connection: component A: external thread M16x1.5; component B: external thread M14x1.5; return hoses Ø 8 mm: transparent, air connection: air plug NW 7.2; incl. instruction manual, No. 16871: HP hose – steel Ø 6 mm, 10 m, union nuts M16x1.5 (solvent-resistant, A component), No. 16870: HP hose – steel Ø 6 mm, union nuts M14x1.5 (solvent-resistant, B component), No. 17625-08: 2C mixing head – steel (2 x HP ball valve, 2 x check valve – stainless steel, mixing tube with 8 x inline static mixer, whip 0.3 m, sliding coupling straight with free passage Ø 2.5 mm, material hose connection: component A: external thread M16x1.5; component B: external thread M14x1.5)

Working pressure – infinitely variable 10 – 100 bar

Delivery rate max. 7.6 l/min

Air consumption 1 m³/min

Air pressure max. 8 bar

Transmission ratio 1:13

Air consumption and delivery rate at 100 bar back pressure (injection pressure)

Air consumption 75 l/min Delivery rate 0,5 l/min

Air consumption 133 l/min Delivery rate 1 l/min

Air consumption 283 l/min Delivery rate 2 l/min

Air consumption 391 l/min Delivery rate 3 l/min

Mixing ratio 1:1

Weight 20.2 kg

L x W x H 58 x 24 x 46 cm

DESOI AirPower L36-2C Set

Moving device, 3 m suction system Ø 20 mm with suction basket Ø 40 mm: component A: transparent, component B: black, 2 x manometer 0 – 400 bar, material hose connection: component A: external thread G1/2″, component B: external thread G3/8″, return hoses Ø 13 mm, transparent, air connection package: claw coupling 42 mm, air plug NW 7.2; incl. instruction manual, No. 16866: HP hose – steel Ø 10 mm, 10 m, union nuts G1/2″ (solvent resistant, component A), No. 16865: HP hose – steel Ø 10 mm, union nuts G3/8″ (solvent resistant, component B), No. 17812-12: 2C mixing head – steel (2 x HP ball valve, 2 x check valve stainless steel, mixing tube with 12 x inline static mixer, whip 0.3 m long, sliding coupling with free passage Ø 2.5 mm, component B: external thread G3/8″)

Working pressure – infinitely variable 5 – 200 bar

Delivery rate max. 20 l/min

Air consumption 2.5 m³/min

Transmission ratio 1:25

Mixing ratio 1:1

Air pressure max. 8 bar

Weight 92 kg

L x W x H 110 x 55 x 65 cm

DESOI PowerInject SP20 110V Set

Moving device, 30 litre plastic material container, splash guard, rotor, stator, infinitely variable delivery control, incl. instruction manual, No. 11403: Quick snap (LP ball valve R1/2″, 5 m material hose Ø 13 mm with Geka coupling lock-type, pressure gauge unit with manometer 0 – 40 bar, free passage Ø 9 mm, spring protection against buckling), No. 21232: LP ball valve R1/2″ (max. 40 bar, mouth piece, detachable double nipple R1/2″)

Supply 110 V/50 – 60 Hz

Motor power 1.8 kW

Working pressure max. 15 bar

Delivery – infinitely variable 0 – 13.5 l/min

Filling height 90 cm

Grain size max. 3 mm

Weight 26 kg

L x W x H 80 x 52 x 90 cm

DESOI PowerInject SP11

Moving device, 80 litre material container, rotor (yellow), stator (yellow), automatic stator puller, remote control with continuous delivery control, pressure gauge unit with manometer 0 – 60 bar and manometric switch, connection material hose mortar coupling type 25, 1 sprayer of silicone, incl. instruction manual

Supply 230 V/50 Hz

Motor power 1.5 kW

Grain size max. 6 mm

Filling height 68 cm

Weight 136 kg

L x W x H 155 x 75 x 71 cm

Rotor/stator – violet ¹ Working pressure* infinitely variable 35 bar Delivery rate* infinitely variable 0 – 5 l/min

Rotor/stator – red ² Working pressure* infinitely variable 40 bar Delivery rate* infinitely variable 0 – 5 l/min

Rotor/stator – yellow ³ Working pressure* infinitely variable 20 bar Delivery rate* infinitely variable 0 – 10 l/min

*max. working pressure and delivery acc. to VDMA 24284

DESOI AirPower S25-3C VA Set

Moving device, 1.5 m suction system Ø 13 mm with suction basket Ø 40 mm: component A, B and rinsing pump: black, 2 x manometer 0 – 250 bar, rinsing pump S25, material hose connection: component A: external thread M16x1.5; component B: external thread M14x1.5; rinsing pump: external thread M12x1.5; return hoses Ø 8 mm: transparent, air connection: air plug NW 7.2; incl. instruction manual No. 16861: HP hose – stainless steel Ø 6 mm, 10 m, union nuts M16x1.5 (solvent resistent, component A), No. 16860: HP hose – stainless steel Ø 6 mm, union nuts M14x1.5 (solvent resistent, component B), No. 16813: HP hose – stainless steel Ø 6 mm, union nuts M12x1.5 (solvent resistant), No. 17764: 3C mixing head – stainless steel (2 x HP ball valve, 2 x HP ball valve steel, 2 x non-return valve, mixing block with 2 x inline static mixer, whip 0.3 mm long, sliding coupling straight with free passage Ø 2,5 mm material hose connection: component A: M16x1.5; component B: M14x1.5; rinsing connection: M12x1.5)

Working pressure – infinitely variable 10 – 100 bar

Delivery rate max. 8 l/min

Air consumption 1 m³/min

Air pressure max. 8 bar

Transmission ratio 1:13

Air consumption and delivery rate at 100 bar back pressure (injection pressure)

Air consumption 83 l/min Delivery rate 0,5 l/min

Air consumption 166 l/min Delivery rate 1 l/min

Air consumption 342 l/min Delivery rate 2 l/min

Air consumption 433 l/min Delivery rate 3 l/min

Mixing ratio 1:1

Weight 29.3 kg

L x W x H 78 x 39 x 80 cm

Rinsing pump S25

Working pressure – infinitely variable 7 – 220 bar

Delivery rate 5 l/min

Transmission ratio 1:28

DESOI AirPower M25C-3C VA Set

Moving device, suction system, 2 x pressure gauge unit with manometer 0 – 250 bar and rinsing pump type S25, incl. instruction manual, No. 16813: HP hose – stainless steel (Ø 6 mm, 10 m long, union nuts M12x1.5, solvent resistant), No. 16860: HP hose – stainless steel (Ø 6 mm, union nuts M14x1.5, solvent resistent, component B), No. 16861: HP hose – stainless steel (Ø 6 mm, union nuts M16x1.5, component A), No. 17764: 3C mixing head – stainless steel (2 x HP ball valve, 2 x HP ball valve steel, 2 x non-return valve, mix block with 2 x inline static mixer, whip 0.3 m long, sliding coupling straight with free passage Ø 2,5 mm; material hose connections: component A: M16x1.5; component B: M14x1.5; flush connection: M12x1.5)

Working pressure – infinitely variable 15 – 220 bar

Delivery rate

– at compressor output of 0.7 m³/min (2 x compressor DESOI R400) max. 8 l/min

– at compressor output of 1.5 m³/min max. 10 l/min

Air consumption 1 m³/min

Mixing ratio 1 : 1

Air pressure max. 8 bar

Weight 45 kg

L x W x H 55 x 48 x 84 cm

Rinsing pump

Working pressure – infinitely variable 7 – 220 bar

Delivery rate 5 l/min

Transmission ratio 1 : 28

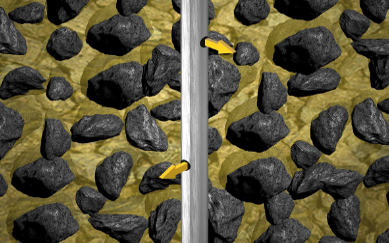

INJECTION LANCES

Ground injection with ram injection lances

For this procedure, steel tubes (lances) with tips are rammed into the soil. Basically, there are two different variants:

lances with lateral outlet openings and fixed tip as well as lances without lateral outlet openings and lost tip. For the variant with fixed tip, the material is injected into the ground via lateral outlet openings. For the variant with lost tip, the injection material runs off the end of the lance. The method is especially suitable for low depths and permeable soils, in practice however, placing depths up to 15 m are realised as well. The length of both variants can be adapted individually in situ according to the requirements. The maximum placing depth depends from the soil conditions.

When injecting below base plates, drill holes have to be made first. For sealing these drill holes, injection packers with connecting sleeves are used.

Advantages:

– Ram injection lances can be combined individually according to the

injection depth

– With ram injection lances Ø 21.3 mm, no annular gap on the outside diameter is produced during ramming, thus no uncontrolled leakage of injection material

– Easy to handle, no need of big machines

Application:

– Determine the remedial action together with a planning specialist, a geotechnician etc.

– Mark the grid according to the rehabiltation concept

– Drive the ram injection lance down to the determined depth using the ramming tool and the pile hammer

– Mount connecting system to the ram injection lance

– Connect material hose and inject the injection material

– Remove connecting system after the injection has been finished

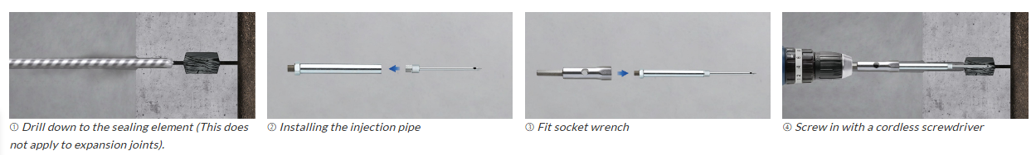

INJECTION NEEDLE PACKERS - EXPANSION JOINT

B-STING® joint injection needle

The B-STING® joint injection needle enables simple and safe sealing of sealing joints in tunnels, especially in segmental tunnels. The joint is sealed by screwing in the B-STING® with a cordless screwdriver and injecting an acrylate or polyurethane-based filler. The B-STING® remains in the component and ensures a permanent seal. There is no need for time-consuming drilling work during application.

NEW is the use of the B-STING® joint injection needle for sealing leaking expansion joints.

Advantages:

No drilling through reinforced concrete

The B-STING®® joint injection needle penetrates the sealing element without removing any material

No material removal => no leaks

Materials used

Acrylate gel

Sealing of leaking

Segment joints

The procedure is basically identical for the subsequent sealing of segments. In this method, an approximately 5 mm thick joint injection needle is screwed into the segment seal via the segment joint using a cordless screwdriver and penetrates the segment seal. An acrylate or polyurethane-based fi ller is injected into the segment joint via a fl at-head gel nipple and the injection tube screwed onto the B-STING®. However, due to the smaller joint width, it is usually necessary to drill out the longitudinal or annular joints of the segments in order to be able to insert the injection pipe with the B-STING® joint injection needle into the joint. As a rule, a drill hole with a diameter of approx. 18 mm is su cient for this. The B-STING® joint injection needle remains in the segment seal and seals the hole permanently.

Our Core Offerings

World-class systems for:

✔️ Crack Injection (PU, Epoxy)

✔️ Curtain Injection for Waterproofing

✔️ Cavity Filling

✔️ Soil Stabilization

✔️ Anchor Grouting

✔️ Microfine Cement Injection

✔️ High-Pressure Injection Packers

✔️ Professional Grouting Pumps

✔️ Modular Accessories for On-Site Efficiency

✔️ Compliant with International Standards

Indian Injection & Grouting Equipment

We maintain ready stock and custom supply of:

Manual, Cement Electric Grouting Pumps

Injection Packers – Mechanical, Rubber, Steel

Cement Slurry Pumps & Hand Grout Tools

Accessories for Low & High-Pressure Injection

MORE ABOUT THE DIFFERENT APPLICATIONS

POLYMERIC FILLING MATERIAL (INJECTION RESIN)

Injection resins can consist of one or two components that react chemically with each other. Initiators and accelerators are mixed in as additional components as required. By injecting polymeric filling materials, various injection targets are pursued, such as sealing of components or the non-positive connection of components. For this purpose, different packer types from the DESOI quality range can be used to successfully carry out an injection task.

MINERAL MATERIAL

In case of crack repair with cement suspension and cement paste, cracked structural elements are repaired by means of non-positive injection. The cracks are injected so that no more water can penetrate after the injection process is completed. The injection material forms a protection against the penetration of aggressive substances and prevents corrosion of the reinforcement. The load-bearing capacity of the structural elements is restored by the frictional connection of the crack flanks.

INJECTION HOSE SYSTEM

Since the early 70s injection hose systems have been used alternatively or in addition to joint profiles and metal water stops. It is an injectable joint filler in tube or channel form. Subsequent leaks can be sealed by injecting polyurethane resin, acrylate resin, cement suspension or cement paste.

Why Rohhri Enterprises LLP?

- Authorized DESOI Distributor in India

- Wide Range of Indian Equipment – Fast delivery & competitive pricing

- Technical Expertise – On-site guidance & after-sales support

- One-Stop Source – From packers to pumps, we’ve got you covered

- Serving Contractors, Waterproofing Experts, and Civil Engineers Across India