Jindal Advanced Material

Exclusive Distributor of Jindal Advanced Materials’ JAM

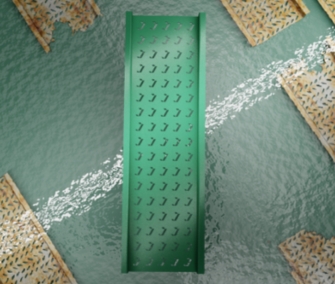

GFRP Rebars for Modern Construction

Rohhri Enterprises LLP proudly partners with Jindal Advanced Materials as the official distributor of their flagship JAM Vantage GFRP Rebars in India. We are committed to delivering high-performance, corrosion-resistant, lightweight composite rebars tailored for modern construction demands.

At Rohhri Enterprises LLP, we take pride in being a trusted distributor of Jindal Advanced Material’s Rebar GFRP (Glass Fiber Reinforced Polymer)—a cutting-edge alternative to traditional steel reinforcement.

Whether you’re working on infrastructure, marine structures, highways, or industrial construction, our GFRP solutions offer superior strength, durability, and corrosion resistance, transforming how reinforcement is done in modern civil engineering.

GFRP Rebars for Modern Construction

Our collaboration with Jindal Advanced Materials allows us to supply GFRP rebars, an innovative alternative to traditional steel reinforcement.

Why Choose Rebar GFRP from Jindal Advanced Material?

✔️ Corrosion-Resistant

Perfect for coastal, marine, and high-moisture environments.

✔️ High Strength-to-Weight Ratio

Lighter than steel, easier to transport and install—without compromising strength.

✔️ Non-Conductive & Non-Magnetic

Ideal for sensitive environments such as power plants, medical facilities, and research labs.

✔️ Cost-Efficient

Reduced maintenance and longer service life offer better value over time.

Industries we serve

Infrastructure Projects

Transportation & Bridges

Marine & Coastal Structures

Tunnels & Dams

Power Plants & Industrial Facilities

MORE ABOUT THE DIFFERENT APPLICATIONS

POLYMERIC FILLING MATERIAL (INJECTION RESIN)

Injection resins can consist of one or two components that react chemically with each other. Initiators and accelerators are mixed in as additional components as required. By injecting polymeric filling materials, various injection targets are pursued, such as sealing of components or the non-positive connection of components. For this purpose, different packer types from the DESOI quality range can be used to successfully carry out an injection task.

MINERAL MATERIAL

In case of crack repair with cement suspension and cement paste, cracked structural elements are repaired by means of non-positive injection. The cracks are injected so that no more water can penetrate after the injection process is completed. The injection material forms a protection against the penetration of aggressive substances and prevents corrosion of the reinforcement. The load-bearing capacity of the structural elements is restored by the frictional connection of the crack flanks.

INJECTION HOSE SYSTEM

Since the early 70s injection hose systems have been used alternatively or in addition to joint profiles and metal water stops. It is an injectable joint filler in tube or channel form. Subsequent leaks can be sealed by injecting polyurethane resin, acrylate resin, cement suspension or cement paste.

Our Commitment

At Rohhri Enterprises LLP, we are committed to supplying high-quality GFRP Rebars with prompt service, technical guidance, and end-to-end support. We work closely with engineers, contractors, and developers to deliver materials that meet performance and safety standards at every level.

Partner With Us

Looking for reliable, corrosion-resistant reinforcement for your next project?

Let’s build the future together with Rebar GFRP.